As technology continues to advance rapidly consumers expect more than just flashy features. They desire devices that are sturdy, dependable, and able to maintain consistent performance over extended periods. This is where the HTOL Reliability Test comes in—a vital procedure used by manufacturers to guarantee their products can withstand the demands of everyday use. Whether it’s a smartphone or an advanced automotive system, knowing this testing process is essential for those interested in the durability and longevity of modern electronic devices. Let’s explore what HTOL testing entails and understand its significance, especially in today’s fast-paced world.

Importance of Durability and Performance in Modern Devices

As technology becomes more integral to daily life, the demand for durable and high-performance devices rises sharply. Consumers expect gadgets to function effectively and last longer under various conditions.

Durability impacts user satisfaction significantly devices that can withstand drops, spills, or extreme temperatures build trust with owners. Users want assurance that their investments will endure.

Performance is equally vital. Slow-loading apps or lagging functionalities frustrate users and degrade their experience. In industries like healthcare and automotive reliable electronics are essential as malfunctions can lead to serious consequences.

With constant innovation, manufacturers must prioritize both durability and performance to meet consumer expectations and remain competitive in a crowded market.

What is HTOL Reliability Test?

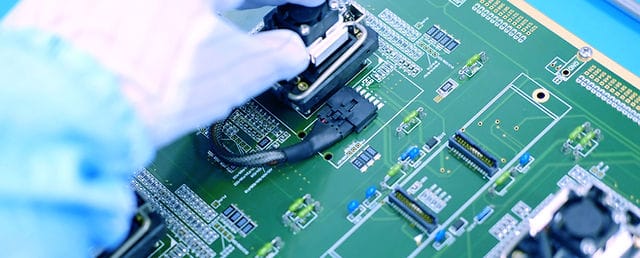

The HTOL (High-Temperature Operating Life) Reliability Test is essential for evaluating the reliability of semiconductor devices under stress by simulating long-term usage at elevated temperatures. Its primary goal is to identify potential failures early in the product lifecycle, enabling manufacturers to predict long-term performance.

During HTOL testing various parameters, such as electrical performance and physical integrity, are monitored. Any anomalies detected provide insights into design weaknesses or material flaws. HTOL is particularly crucial in industries like automotive electronics and medical devices where device failure can have serious consequences, ensuring safety and functionality throughout their lifespan.

Benefits of HTOL Reliability Test

The HTOL (High-Temperature Operating Life) Reliability Test offers several significant benefits that positively impact both manufacturers and consumers:

- Enhanced Product Quality: HTOL testing helps manufacturers identify potential failures during the production process. By detecting issues early, companies can implement corrective measures before products reach the market. This proactive approach results in higher-quality products, reducing the likelihood of defects that could affect performance or customer satisfaction.

- Cost Reduction: By identifying defects at an early stage, HTOL testing minimizes the risk of warranty claims and product returns. Along with saving time and money, this maximizes resource allocation for producers. Fewer returns mean lower costs associated with repairs, replacements, and customer service, allowing companies to invest in other critical areas of their operations.

- Increased Consumer Trust: Consumers tend to favor products that have undergone thorough reliability testing. When customers know a product has passed rigorous assessments like HTOL, they are more likely to trust its quality and performance. This trust can lead to increased brand loyalty, as satisfied customers are more likely to make repeat purchases and recommend the brand to others, potentially boosting sales.

- Promotion of Innovation: HTOL testing provides valuable insights that can guide design improvements. The data collected during testing helps engineers identify areas for enhancement in product design, leading to better performance, durability, and overall user experience in future iterations. This continuous improvement cycle fosters innovation within manufacturing teams, encouraging them to develop advanced products that meet evolving market demands.

In summary, HTOL testing is a vital tool that enhances product quality, reduces costs, builds consumer trust, and drives innovation, benefiting both manufacturers and consumers in the competitive marketplace.

Real Life Examples of HTOL Testing

HTOL testing is essential across various industries, particularly in consumer electronics. Leading smartphone manufacturers use HTOL tests on chips to ensure durability under extreme conditions. In the automotive sector, electric vehicle components undergo rigorous assessments to identify potential failures before market launch, ensuring long-term reliability.

Medical device manufacturers test sensors and control systems with HTOL to ensure they can endure extended use, prioritizing patient safety. Aerospace firms also utilize HTOL testing for critical avionics systems, using results to enhance durability and dependability in challenging environments. These examples highlight the importance of HTOL reliability tests in reinforcing product quality and customer trust across multiple sectors.

Challenges and Limitations of HTOL Testing

HTOL (High-Temperature Operating Life) testing is an essential process for evaluating the reliability of semiconductor devices. However, it comes with several challenges and limitations that manufacturers must consider:

- Need for Specialized Equipment: HTOL testing requires advanced and often expensive equipment to create controlled environments with elevated temperatures and voltages. This specialized setup may be financially burdensome for smaller manufacturers, limiting their ability to conduct these tests effectively.

- Extended Test Duration: The nature of HTOL testing involves exposing devices to high temperatures over prolonged periods to simulate long-term use. This extended duration can delay the overall product development timeline, impacting time-to-market for new devices.

- Limited Real-World Simulation: While HTOL tests provide valuable insights, they do not encompass all real-world conditions. Factors such as humidity, mechanical stress, and variations in operating environments are often not considered, which can lead to unexpected failures once the devices are deployed in actual use.

- Complex Data Interpretation: The data generated from HTOL testing can be intricate and difficult to interpret. Engineers must analyze various parameters to make accurate predictions about long-term performance, which requires significant expertise and can lead to potential misinterpretations if not done carefully.

- Risk of Over-Reliance: There is a danger in relying solely on HTOL test results for assessing product reliability. While HTOL provides important information, it should be complemented with other testing methods to ensure a thorough evaluation of product durability. Without a holistic approach, manufacturers might overlook critical failure modes that could arise in real-world applications.

By recognizing these challenges, manufacturers can better prepare for the complexities of HTOL testing and develop more reliable products through comprehensive evaluation strategies.

Future Developments in HTOL Testing

As technology advances, HTOL reliability testing is evolving, with a focus on automation and machine learning integration to improve accuracy and efficiency in detecting potential failures. Advanced algorithms will enable faster data analysis, identifying failure patterns that might be missed by human analysts.

Another trend is the incorporation of real-time monitoring systems into testing environments, providing continuous feedback throughout the HTOL process for immediate adjustments. Researchers are also exploring new materials for semiconductor components to enhance thermal performance, potentially leading to more reliable devices with longer lifespans.

Additionally, collaboration among industry leaders is increasing, facilitating the sharing of insights and innovations to accelerate advancements in testing methodologies, making them more robust against future challenges.

Conclusion: Why You Should Care About HTOL Reliability Test

Understanding HTOL (High-Temperature Operating Life) Reliability Testing is crucial for anyone involved in electronics and device manufacturing. As modern devices become more complex, ensuring their durability and performance is essential. HTOL testing simulates real-world conditions, helping predict the long-term reliability of electronic components.

This method not only identifies potential failures before products reach consumers but also enhances customer satisfaction through improved reliability. By investing in thorough HTOL testing, companies can reduce warranty costs, enhance brand reputation, and build consumer trust.

For engineers and stakeholders, staying updated on HTOL developments leads to better material and design decisions. Embracing HTOL allows businesses to remain competitive while delivering high-quality products that meet market expectations. As technology advances rapidly, understanding the nuances of reliability tests like HTOL becomes increasingly relevant, providing valuable insights into what makes devices reliable.